On March 22, 2025, China Integrated Circuit Innovation Alliance officially announced the winners of the 8th “IC Innovation Award”. GalaxyCore’s self-developed Touch and Display Driver Integrated (TDDI) Chip GC7272 was awarded the “Achievement Industrialization Award” due to its shipment of over 100 million units and the successful industrialization of its proprietary technology. This award not only recognizes GalaxyCore’s technological innovation but also strongly affirms its industrialization achievements in DDIC.

The rapid evolution of generative AI makes it possible for smart (AI) glasses to walk out from science fiction into reality and become good assistants in our everyday life:

• Serving real-time communication with overseas colleagues during multinational meetings.

• Acting as your memory assistant, helping you “recall” misplaced items.

• Alerting you when you start to feel drowsy – like an invisible co-driver, safeguarding your travel safety at all times.

• When you want to capture a stunning view but have no hands free, simply whisper “Take a photo”, and your glasses will instantly freeze the moment, ensuring you never miss a heartbeat.

......

AI glasses are shifting from “geek gadgets” to mainstream consumer products, and market data underscores the explosive potential of this trend. According to the Wellsenn XR report[1], global AI glasses shipments reached 1.52 million units in 2024, with a projected surge to 3.5 million units in 2025, indicating a year-over-year growth rate of 130%.

Behind this exciting momentum, however, lies a major technological challenge. The CMOS Image Sensor (CIS), the “eye” of AI glasses, is being tasked with ever-greater expectations. These sensors must find a balance between compact size and powerful performance. How to achieve stronger imaging capabilities within the tiny confines of a frame smaller than 1cm² and a total device weight under 40 grams? This is a critical technical question the industry must answer.

GalaxyCore’s new high-performance CIS packaging technology – TCOM (Tiny Chip On Module) packaging – was developed precisely to address this challenge.

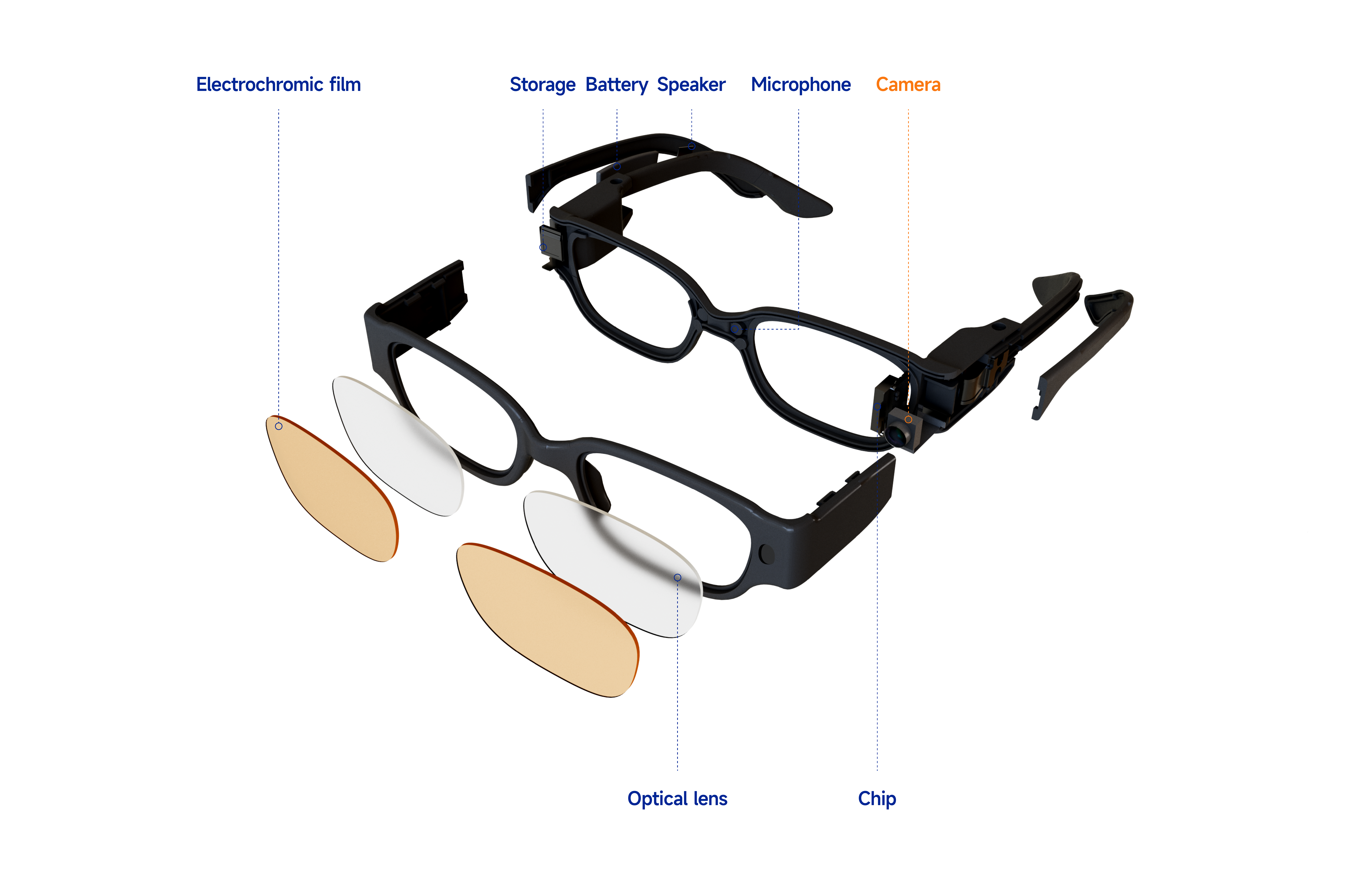

Exploded diagram of AI glasses

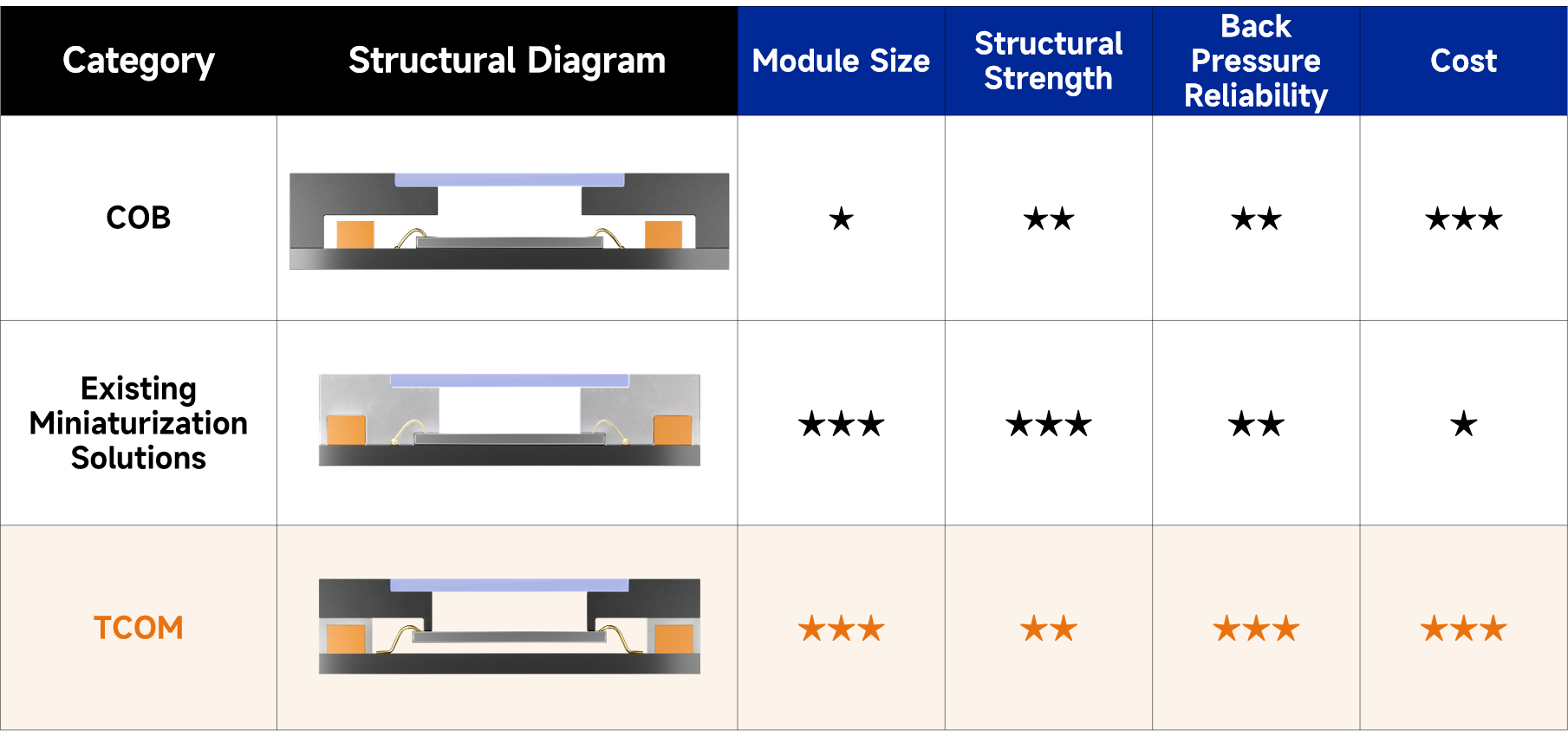

TCOM is an upgraded version of GalaxyCore's high-performance COM (Chip On Module) packaging technology, specifically developed for space-constrained applications. The COM packaging technology rivals high-end COB (Chip On Board) solutions, offering superior optical system performance and enhanced back pressure reliability. In long-term mass production, COM technology has gained high recognition by customers, with cumulative shipments exceeding 500 million units.

Click the link to learn more about the COM solution

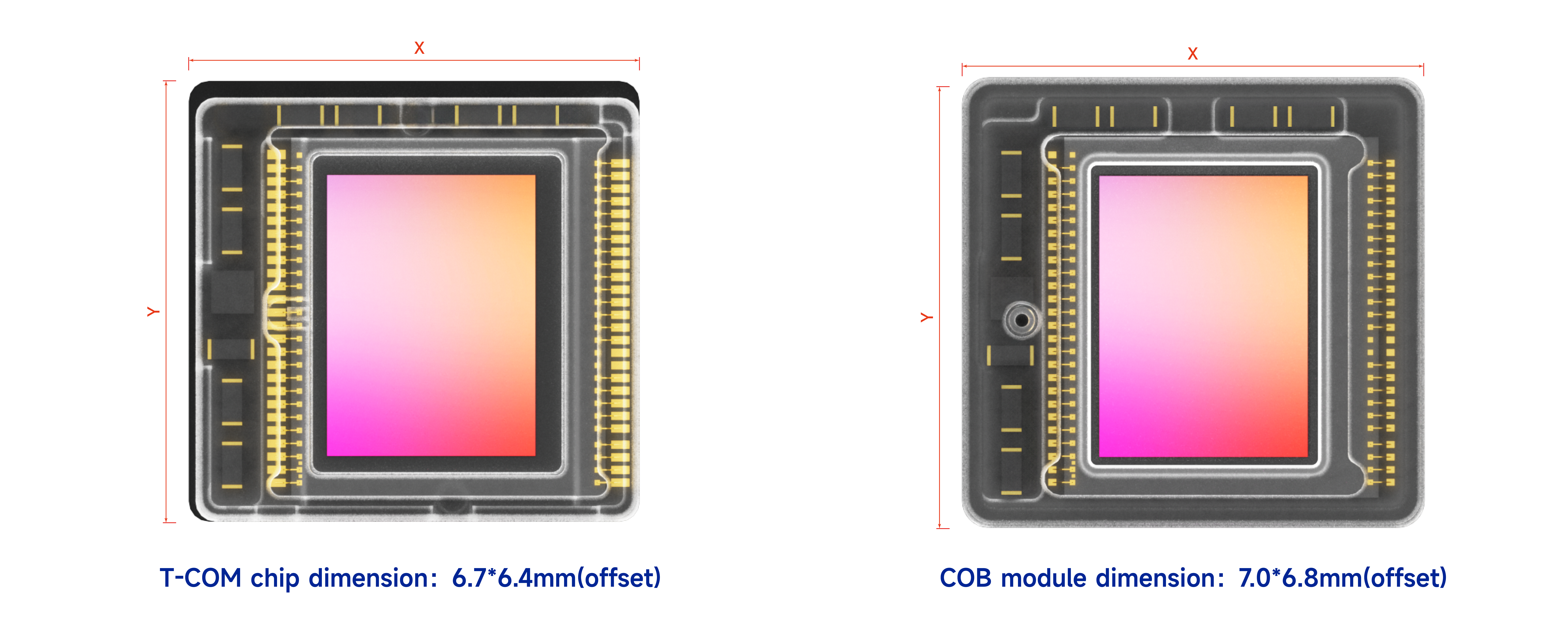

Building on this foundation, TCOM has upgraded structure and technology that enables the integration of high-performance imaging modules within limited spaces. Compared to COB-packaging chips of the same specification, TCOM modules achieve a 10% reduction in size. Relative to existing miniaturization solutions in the industry, TCOM offers significant cost advantages and superior back pressure reliability.

GC13B0 TCOM & COB chip size comparison

How did GalaxyCore achieve this breakthrough design? Current miniaturized CIS packaging solutions face a dual challenge of high costs and limited back pressure reliability. These solutions, based on the COB structure, use specialized molding processes and equipment to encapsulate components, chips, and circuit boards. This achieves module size reduction and strong structural integrity, but comes with relatively high costs. That aside, CIS sensors mounted directly onto the PCB are more sensitive to back pressure, leading to higher susceptibility of the spatial frequency response (SFR) to degradation.

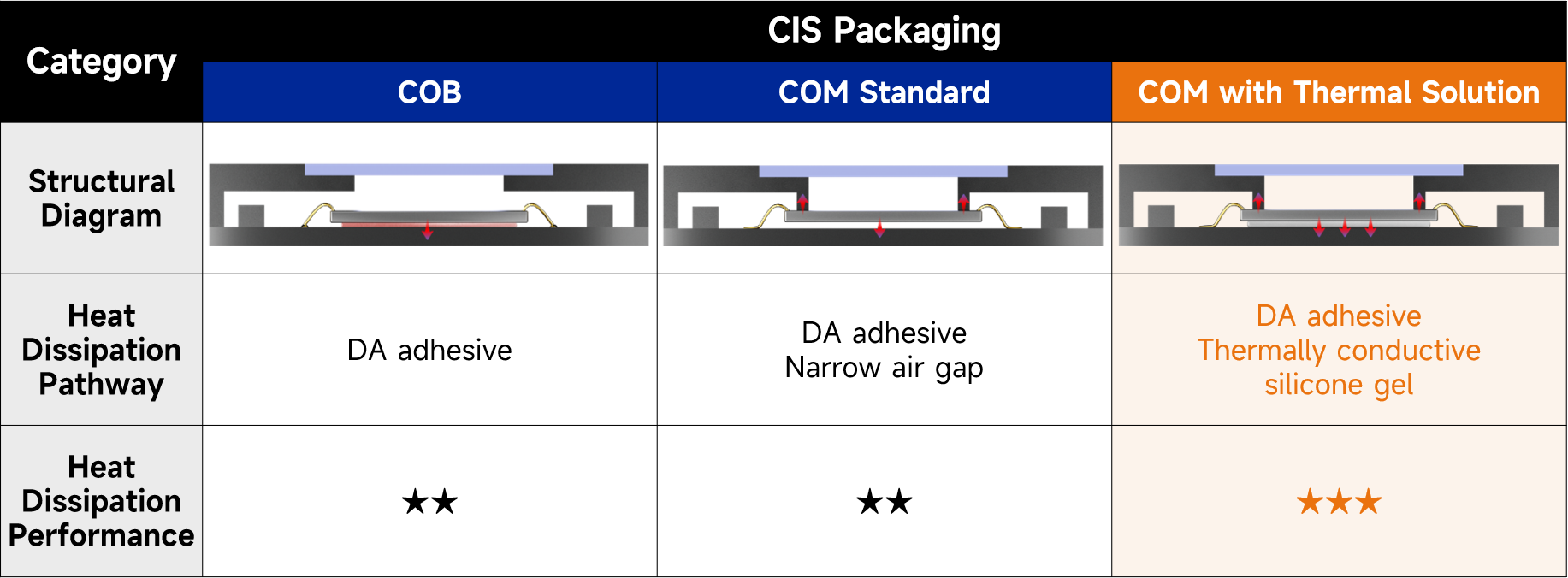

Structural diagram of the COM thermal solution and heat dissipation performance comparison of different solutions

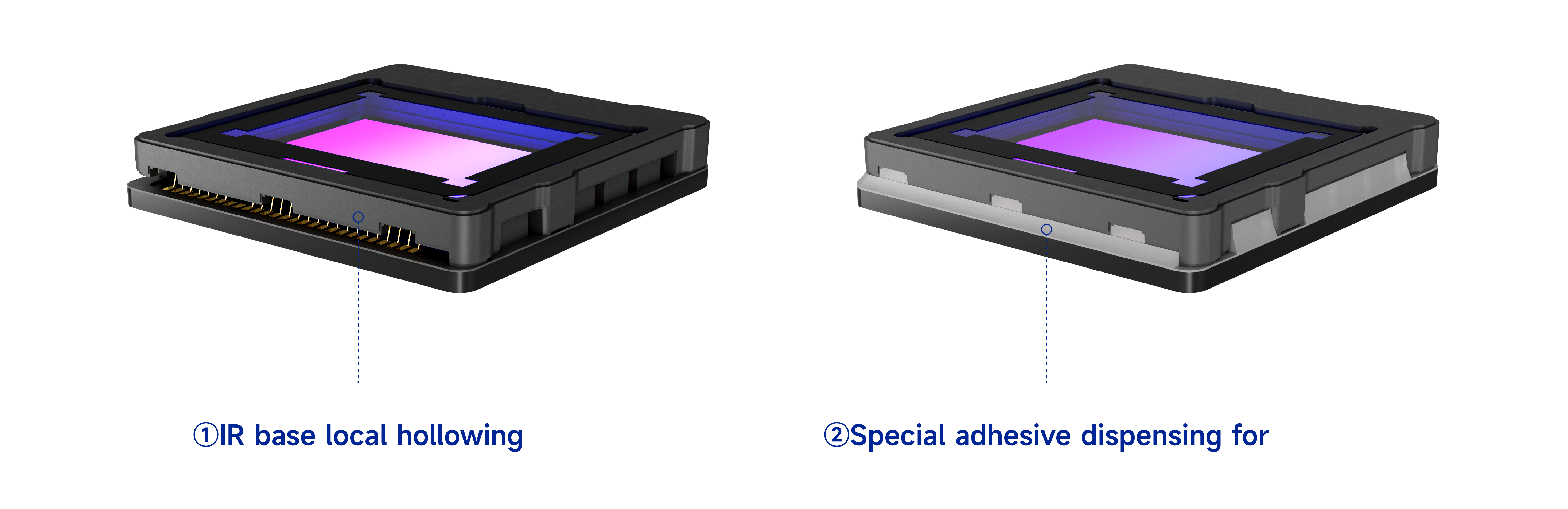

TCOM achieves miniaturization concurrently with superior performance and high cost efficiency. First, IR base design optimization. The IR base on the side of the gold wires connecting the CIS and FPC is locally hollowed out, with its width reduced by approximately 10%. Then a special dispensing process and equipment are used to apply adhesive at a certain angle on both sides of placed components and between the components and the IR base.

TCOM process flow illustration

This peculiar design enables the TCOM module to have shorter length and width without sacrificing its structural strength, rendering it suitable for the compact “frame-as-lens” structure of AI glasses, leaving more internal space for additional components, and making “all-day seamless wear” possible.

From AI Glasses to Smartphones: Expanding More Possibilities

The application scenarios for TCOM technology go far beyond AI glasses. In devices like smartphones and tablets, where every millimeter matters, TCOM packaging technology opens up new possibilities.

Take smartphones as an example: TCOM can further shrink the front camera module, making its placement more flexible and closer to the screen edge to enhance the full-screen display experience. For rear cameras, TCOM helps reduce the module height and minimize camera bumps, so as to make phones thinner, thereby boosting overall device competitiveness.

As devices become more compact, heat dissipation becomes even more critical. To address this challenge, GalaxyCore has developed a COM solution with enhanced thermal performance.

A smartphone that continuously captures high-resolution, high-frame-rate videos often heats up. Poor heat dissipation will affect the device’s stability and safety. According to statistics[2], for every 10°C rise in the temperature of electronic components inside a smartphone, their reliability drops by 50%. Notably, high temperatures account for up to 55% of electronic component failures.

The COM thermal solution builds upon traditional DA adhesive materials by the additional use of high-efficiency thermally conductive silicone gel, which further improves heat dissipation. Measured data shows that, in a 50MP 1.0μm CIS module under 4K 60fps mode, COM packaging can reduce the module temperature by about 5°C compared to COB packaging, equating the effect of an external cooling fan to the phone!

Comparison of COB, existing miniaturization solutions and TCOM

In AI glasses, smartphones and other devices, every gram of reduction in weight, every millimeter of release in space, and every single degree of drop in temperature contributes to a leap in user experience. GalaxyCore’s COM series packaging solutions redefine the new standard for CIS packaging, simultaneously achieving miniaturization, sound heat dissipation, high performance and high reliability.

This creates a possibility that in the near future, “imperceptible” smart glasses will allow us to see a blended world of virtual and real, as well as a future where technology and user experience resonate in perfect harmony – intelligent enough, and yet light enough to feel almost weightless.

Currently, GalaxyCore’s 5MP CIS has already entered mass production for AI glasses projects. In the future, GalaxyCore will continue its focus on CIS, and combine the use of high-performance packaging solutions like the COM series to equip devices with lighter and smarter “eyes”.

References:

[1] Wellsenn XR: AI Smart Glasses Shipment Tracking Report 2024

[2] Chemical Communications: Smartphone Heat Dissipation: How Your Smart Companion Stays Coo