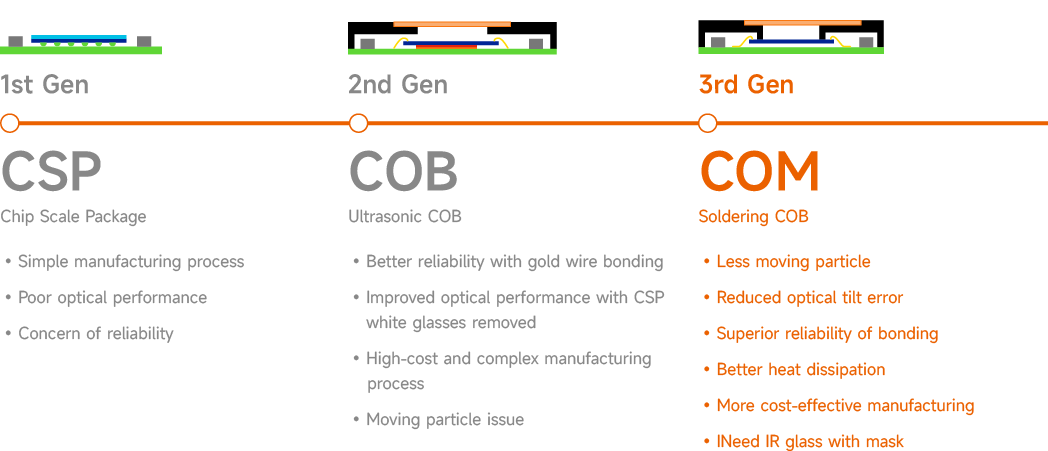

CIS PACKAGING SOLUTIONS

COM Packaging

3rd generation CIS soldering packaging technology independently developed by GalaxyCore

The front end of the line of camera module is conducted in the clean room with cleanliness class 100. The COM chip is packaged by fully automatic high-precision equipment and 100% functionally and visually inspected before delivery. Automated SMT and soldering devices are used in the back end of line (BEOL), which ensures the performance and quality of modules.

OIS Packaging

GalaxyCore’s independently developed sensor shift optical image stabilization solution adopts advanced SMA (Shape memory alloy) actuation technology. Combined with GalaxyCore’s high-end and high-resolution CMOS image sensors, it forms an integrated OIS and CIS turnkey solution. Only lens, AF motor attachment and AA are needed at the module house, which significantly reduce the production complexity for module houses.

The unified OIS packaging design delivers first-class sensor shift optical stabilization performance and image quality to customers, while offering a cost-effective solution.

Shape Memory Alloy

Image Sensor Three-Axis (X, Y, Z ) Shake Compensation

GalaxyCore TSA