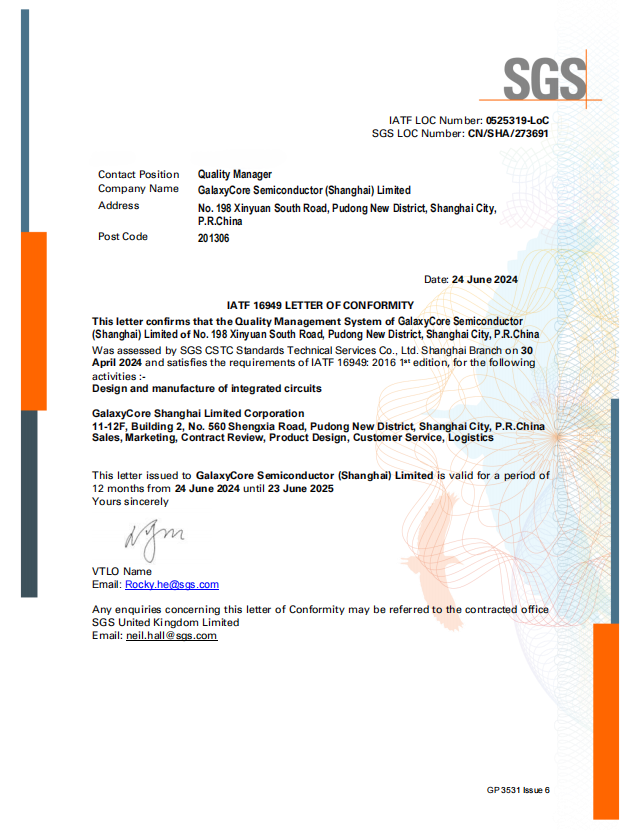

Automotive chips directly affect the safety, performance, and user experience of automobiles, with a lifespan of over 15 years imposing strict requirements on quality and reliability. GalaxyCore’s Lingang Fab has successfully obtained the IATF16949:2016 Automotive Quality Management System Conformance Certification (referred to as “IATF16949”), signifying that GalaxyCore’s Lingang Fab has reached the high standards of the global automotive industry in terms of the design, manufacturing, and customer service of automotive electronics, thus laying a solid foundation for GalaxyCore to enter the automotive pre-installed products market and provide high-quality automotive grade products for the industry.

The International Automotive Task Force (IATF) is composed of major global automotive manufacturers, and the IATF16949 is a globally recognized quality management system standard for the automotive industry. It focuses on continuous improvement, defect prevention, and supply chain management, requiring companies to achieve high level of normalization and standardization in product design, research and development, production, installation, and service, so as to provide products with high quality and high reliability. As such, it is regarded as the access pass to enter the global automotive industry.

GalaxyCore is actively expanding its presence in the automotive electronics market, particularly in the CMOS image sensor products segment of the automotive pre-installed products market, so as to respond to the rapid growth of automotive assisted driving, autonomous driving, and driver cabin applications. GalaxyCore’s Lingang Fab is committed to empowering the research and development and manufacturing of high-performance image sensors and other products, effectively improving the efficiency of research and development and manufacturing by leveraging its advanced production line and strict quality control system. This certification is strong proof that GalaxyCore is capable of using its in-house Fab to develop customized high-quality and highly reliable CMOS image sensors and other imaging solutions for automotive manufacturers and tier-1 suppliers.

Automated Advanced Manufacturing Guaranteeing Both Quality and Efficiency

GalaxyCore’s Lingang Fab boasts highly automated manufacturing processes, which operate 24/7 throughout the year by leveraging cutting-edge equipment and intelligent production methods. It has achieved data connectivity of key processes and remote monitoring and operation of production data and equipment data, resolving relevant problems in the production process in real time and on the spot, thus comprehensively improving the safety, stability, and reliability of product manufacturing.

Strict Quality Management System Adding Value to Quality

GalaxyCore’s Lingang Fab has established a comprehensive quality management system from research and development, production to shipment, including customer and R&D quality management, incoming material quality management, process quality management, shipment quality management, laboratory management, quality system management, etc., so as to ensure that every aspect of the products from design to production meets the highest global quality system standards.

GalaxyCore will leverage the advanced production line and quality management system of its Lingang Fab to accelerate its product development and market expansion in the automotive electronics sector and collaborate with global automotive industry chain partners to jointly promote the development of the automotive industry towards a smarter and safer future.

Click on the video to learn more about GalaxyCore’s Lingang Fab.